Views: 77 Author: Site Editor Publish Time: 2026-01-24 Origin: Site

In the window treatment business, "light control" is one of the most common reasons for customer returns.

We often hear retail buyers ask: "Why did my customer complain that these blackout curtains aren't dark enough?" or "Why are these curtains so stiff?"

The problem usually lies in the confusion between two industry terms: Room Darkening (Dim-out) and 100% Blackout.

As a manufacturer, UVAN wants to help you choose the exact fabric construction for your target market. Here is the technical breakdown of the differences and how to source the right one for your 2025 collection.

When a product is labeled "Room Darkening," it typically blocks 70% to 90% of sunlight. It dims the room significantly but does not create pitch-black darkness.

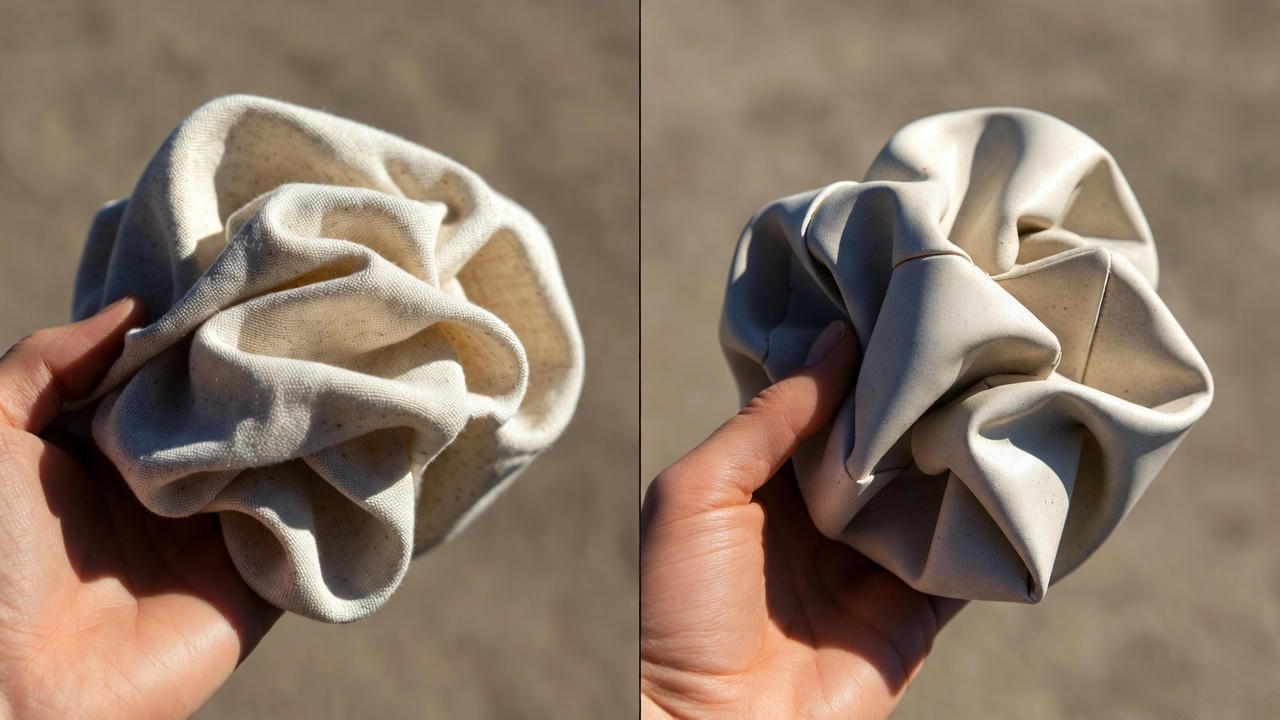

This fabric is created using a physical weaving technique.

Layer 1: The front face (printed or solid color).

Layer 2: A middle layer of black yarn (this is the magic ingredient that absorbs light).

Layer 3: The back face.

Soft Hand-Feel: Because there is no chemical coating, the fabric drapes beautifully and feels soft like standard cloth.

Machine Washable: Very durable and easy to care for.

Lower Cost: Generally cheaper to produce than coated fabrics.

Living rooms and dining rooms where users want privacy but not total darkness.

Customers who prioritize style and drape over function.

True "Blackout" curtains must block 100% of incoming light. If you hold a flashlight behind the fabric, no light should pass through.

This involves applying layers of acrylic foam or silicone to the back of the base fabric.

2-Pass Coating: A grey layer + a white layer.

3-Pass Coating: A white layer + a black layer + a white layer (The highest standard).

Total Darkness: Perfect for shift workers, nurseries, or media rooms.

Thermal Insulation: The coating acts as a barrier against heat in summer and cold in winter, saving energy costs.

Sound Dampening: The added density helps reduce street noise.

Stiffness: The fabric can feel slightly stiffer than triple weave.

Care: Some lower-quality coatings can peel if machine washed incorrectly (though UVAN uses high-grade durable coatings).

Traditionally, it is difficult to print high-quality designs on blackout fabrics because the textures can be rough or the coating interferes with heat transfer.

At UVAN, we have optimized our digital printing process for both types:

On Triple Weave: We ensure the black yarn in the middle doesn't dull the vibrancy of the printed colors on the surface.

On Coated Blackout: We use a specialized "soft-touch" coating base that accepts ink perfectly, allowing for photo-realistic prints on a 100% functional blackout curtain.

To maximize sales and minimize returns, we recommend a "Good, Better, Best" strategy:

Entry Level: Stock "Room Darkening" (Triple Weave) in trendy prints for general home decor shoppers.

Premium Level: Stock "100% Blackout" (Coated) for specific functional needs (Bedroom/Nursery) and market them as "Thermal/Noise Reducing" to justify the higher price point.

Understanding the technical difference between a physical weave and a chemical coating is the key to managing customer expectations.

Whether you need the soft drape of a Room Darkening curtain or the heavy-duty performance of a 100% Blackout, UVAN can manufacture both with your custom designs.

Need to see the difference yourself?[Contact UVAN] to request a sample kit containing swatches of both Triple Weave and Coated Blackout fabrics.